Precision. Integrity. Reliability.

Why Quality is Non-Negotiable

Our Commitment:

- OEM-Standard Guarantee

- Zero Tolerance for Failure

- Full Batch Traceability

Our Gallery

The 7-Point TQC Process

We use advanced Non-Destructive Testing (NDT) techniques, such as **X-Ray Fluorescence (XRF) analysis**, to confirm the precise chemical and structural composition of the raw materials. This ensures the material matches required specifications for heat, stress tolerance, and durability.

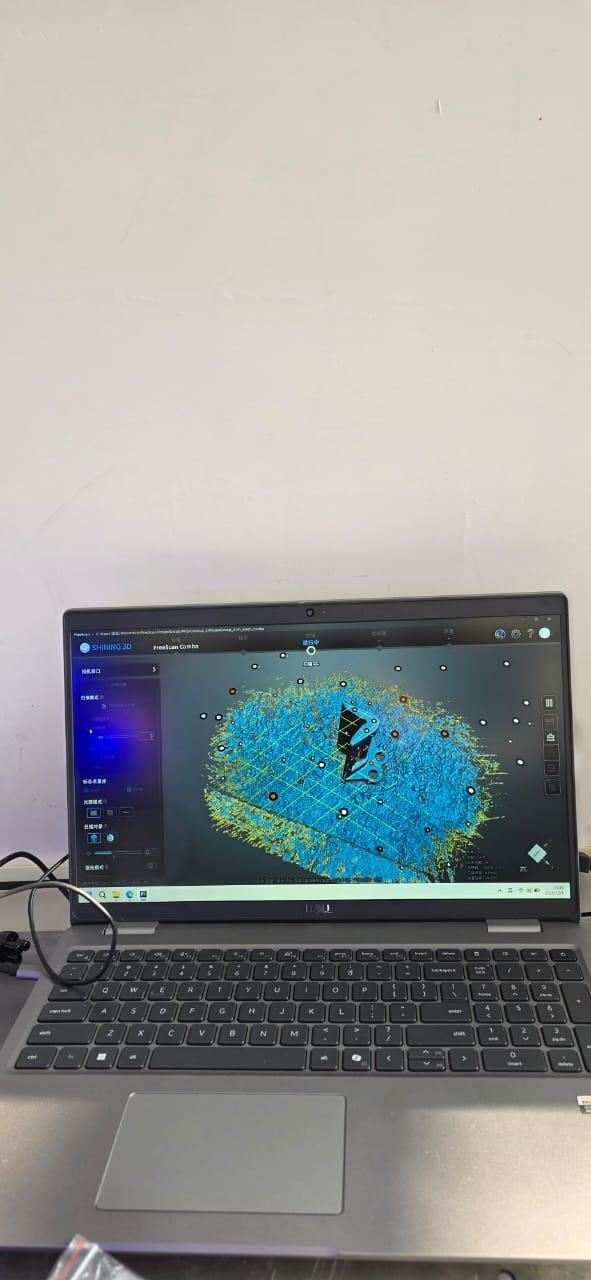

Precision is key. Our engineers verify all critical measurements—tolerances, threads, fits, and surface dimensions—using calibrated digital instruments and **Coordinate Measuring Machines (CMM)**. This guarantees seamless integration and optimal performance within your heavy equipment.

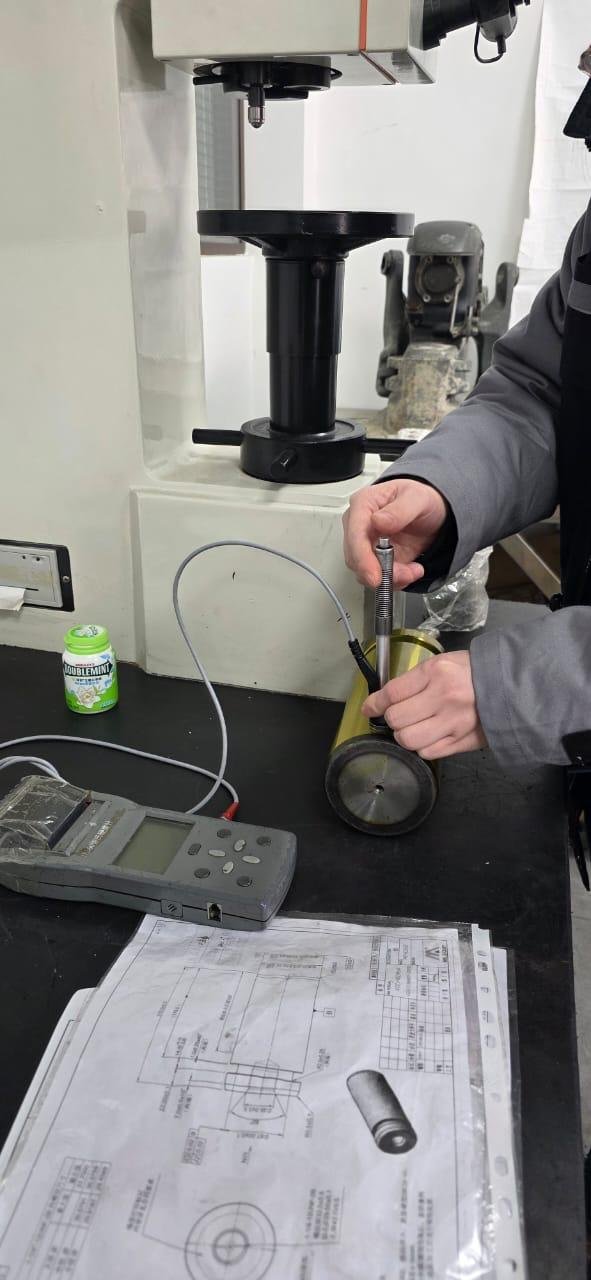

We inspect the surface finish for critical factors like corrosion resistance (via salt spray testing simulation) and required surface hardness (via Brinell/Rockwell testing). This step is vital for components exposed to friction and environmental wear, such as hydraulic pistons, gears, and shafts.

For components like hydraulic pumps, valves, and cylinders, we conduct rigorous **in-house pressure and leak testing**. We cycle the parts under simulated operational loads to ensure seal integrity, fluid dynamics efficiency, and component strength under extreme pressure.

Gaskets and seals are checked for elasticity, chemical compatibility, and dimensional conformity. Failure in a seal leads to fluid contamination and system breakdown; thus, we guarantee their resilience against operating temperature and fluid types.

Every approved part is logged using a unique serial or batch number, linking it to its original manufacturer, material certificate, and the results of our TQC report. This provides a complete audit trail for compliance and warranty assurance, accessible to the client upon request.

The checked and approved part is given specialized protective packaging (e.g., vacuum sealing, anti-corrosion wrap, reinforced crating) designed to prevent environmental damage (moisture, impact) during transit from our hub to your site.

Specialized Expertise for Every Component

Engine Components

Focus on thermal stability, casting integrity, and wear-resistance for pistons, liners, and gaskets operating under extreme heat and pressure.

Hydraulic Systems

Dedicated functional testing for pumps, cylinders, and seal kits to ensure absolute fluid power integrity and zero leakage under maximum operating pressure.

Ground Engaging Tools (GET)

Hardness, stress-point analysis, and metallurgy testing for maximum lifespan of buckets, teeth, and cutting edges in abrasive mining and quarrying applications.

Electrical Systems

Verification of wiring harnesses, sensors, and controllers for continuity, insulation integrity, and OEM software compatibility to prevent electronic failure.

Targeted Testing for Key Components

Engine Components

Focus on thermal stability, casting integrity, and wear-resistance for pistons, liners, and gaskets.

Hydraulic Systems

Pressure and leak testing for pumps, cylinders, and seal kits to ensure absolute fluid power integrity.

Ground Engaging Tools (GET)

Hardness testing and stress-point analysis for buckets, teeth, and cutting edges.